Supply Strategies

Always on the safe side with the right strategy

Companies are probably most afraid of long and unplanned downtimes within production. High numbers of failures and the resulting costs are the consequences. The difficult task of avoiding such situations within the value chain is left to the maintenance departments of the companies, which often have few resources, time and means at their disposal to be able to master this task successfully under the best possible conditions. But where are the concrete problems hiding, which nevertheless always prolong downtimes? Is it a lack of or incorrectly planned inventories, procurement of obsolete or temporarily obsolete spare parts via the manufacturer, machine builder and service provider, or is it the insufficient budget for stocking and maintaining spare parts in the warehouse? Unfortunately, it is the combination of all these and many more hurdles that makes maintenance so complex nowadays. Therefore, EICHLER GmbH deals with process-oriented individual supply strategies that can be flexibly integrated into almost any company in order to solve individual problems step by step and thus support your maintenance with targeted measures. To be able to guarantee fast response times in your production, the solution is often the supply strategy mix of a functioning inventory combination with proactive preventive measures and professional repairs. Within these supply strategy combinations, there are some additional tasks that might be difficult to master on your own. For example, the conditions to create an ideal inventory are sometimes not easy, if for some even unthinkable to implement. In the long-term storage of electronic units, it is a question of finding the ideal mix in warehousing to meet the requirements of individual components. From a purely physical point of view, there are materials within individual electronic components that should ideally be stored under high humidity, as well as components that should ideally be stored in a vacuum.

Conditions for assembly storage

Storage Temperature

The storage temperature should be close to the normal room temperature of approximately 20°C.

Humidity

The most difficult compromise in the storage of assemblies is sought in the humidity. However, since most components prefer a rather low humidity, about 20% - 30% is an acceptable value here.

Periodic Energization

Regular energization of assemblies and panels, formation of inverters and lubrication runs of motors are an indispensable factor in a functioning storage system. Depending on the requirements of each unit, the rhythm of this task may vary.

Professional Packaging

To minimize additional external influences and make them harmless for electronics, the right packaging is also important. Here it is important to ensure that antistatic packaging is used and that it is completely airtight so that particles in the air, unwanted moisture or similar cannot penetrate.

Market Observation

An inventory is often oversized or undersized due to constant market fluctuations, but rarely exactly suitable. Therefore, it is even more important to react regularly to market situations. If unplanned obsolescence, changes in the used parts market and/or demand occur, adjustments to inventory levels are necessary.

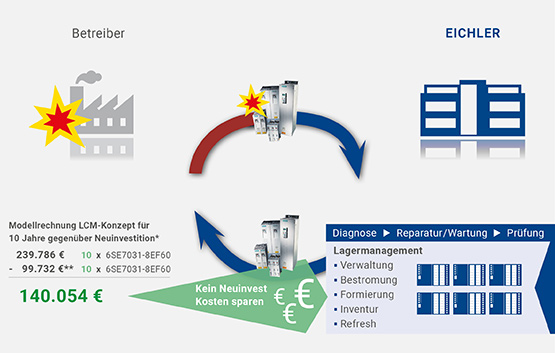

Full Service Warehouse Management

The full service warehouse management is a fully comprehensive warehousing, which includes all technical function maintenance measurements.

Beyond the warehousing and technical challenges, EICHLER takes over the controlling of storage times and market observations. Thus, the stock management can be dynamically adapted to the prevailing conditions at any time. This is accompanied by the guarantee of being able to offer repairs for the agreed contractual products over the associated period.

Reservation of Spare Devices

The reservation of replacement devices can be regarded as an insurance policy. This grants the possibility, in the agreed period of time, to purchase a unit from stock even in the event of machine downtime. The particular advantage is that an investment does not have to be made until it is needed. This means that the strategy naturally also includes the possibility of repairing the agreed contractual products over the entire term of the contract, should the market change.

Strategic Repair Management

Strategic repair management is the insurance of having a repair guaranteed. The risk of not being able to have a repair carried out at some point is thus eliminated. The big challenge then lies with EICHLER, which has to deal with its internal obsolescence management to ensure the correct stocking of repair parts, the early substitution of obsolete repair parts and the provision of test equipment.

Periodic Maintenance and Refresh Models

Our periodic maintenance and refresh models are based on the principle of full-service warehouse management. In this strategy, the customer stores his own units completely himself and leaves all technical tasks for function maintenance and correct storage packaging to EICHLER. In addition, EICHLER again takes over tasks such as controlling of storage times and observations on the market.

Full service warehouse management is the most commonly used supply strategy mix

The full service warehouse management is not without reason the most frequently claimed supply strategy, because as the name "full service" already reveals, we already find the necessary supply strategy mix in this type of our service. The basic principle is based on a functioning warehousing system. The stored units are in your possession, which you either already have or still acquire subsequently. The stock-keeping is realized divided with you and with EICHLER in the warehouse, i.e. you keep a safety stock in order to be able to react fast and EICHLER keeps the remaining stock. These stocks are subject to the necessary technical tasks, which are necessary to keep a unit functional within the storage. Thus, EICHLER realizes a concept with you that includes the regular technical tasks. These measures include the stock at EICHLER as well as the stock at your site. This means that your bearing rotates constantly and functionality is permanently ensured. Should a defect then occur in your machine or system, you have the possibility to react quickly with a 100% functional unit. You repair the defect and send a message to EICHLER that your stock needs to be replenished. Subsequently, you send us your defective unit for repair and we can restore the basic condition by returning it to your EICHLER warehouse. If a unit is irreparable, we will also always try to procure a new one and include it in the concept. Should your needs ever change, this concept is so flexible that this is possible at any time and the total quantity can be adjusted up or down.

Summary of included services:

- Storage of your devices at EICHLER

- Refresh, forming/stressing, testing of your units according to individual technical requirements

- Repair safety of your units despite obsolete product status

- Market observation with joint determination of requirements

- Permanent contact person for you

EICHLER life cycle management consists of three easy steps...

Your Personal Contact

- Sustainably increase plant availability

- Life cycle management / obsolescence management

- Configuration management

- EICHLER Life Cycle Check / risk analysis

- Supply strategies / Warehousing and repair management

Do you have any questions, need further information or a detailed consultation? We are at your disposal:

patrick.kroiss@eichler-service.de

+49 8196 9000-302.