Configuration Management

Configuration Management

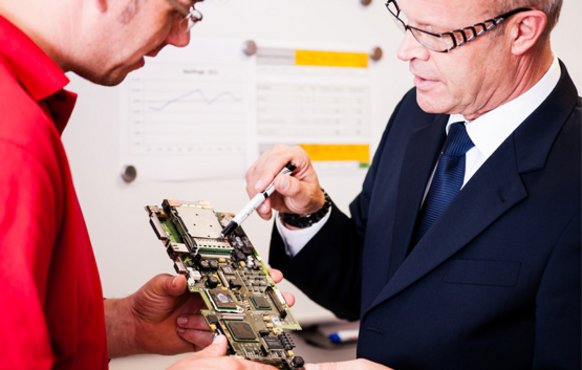

Configuration management is defined according to ISO 10007:2017. Configuration management is a management activity that provides technical and administrative direction of the entire product life cycle, product configuration units, and product configuration-related specifications.

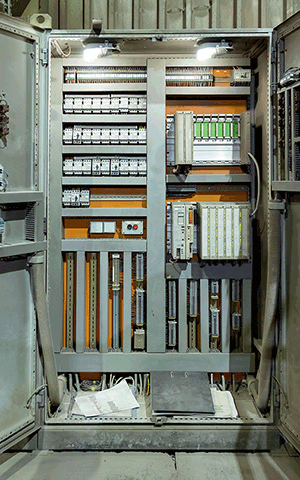

Basically, configuration management helps plant operators and maintainers to keep track of which manufacturers, which units, in what quantity to versioning, are used in each machine or plant, under what conditions.

Despite continuously increasing innovation cycles in the field of electronic assemblies and the associated component obsolescence, the planned operating times of machines and systems in industry continue to rise. Among our customers, operating times of between 20 and 30 years are by no means uncommon. Frequently, knowledge in a company becomes obsolete faster than machines and plants are rebuilt. This makes it all the more important to maintain proper documentation throughout the entire product life cycle. But it is precisely here that we are confronted with a wide variety of difficulties. The most noticeable problems are time and resources, which are unfortunately often lacking in maintenance. Thus, the task management is even more far-reaching than it seems at first glance.

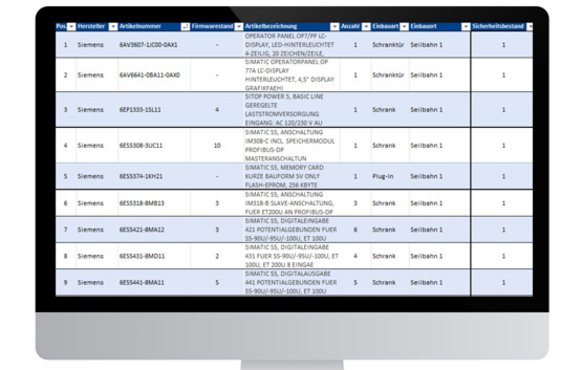

The attached Excel template can be used to assist you with creating your inventory.

Configuration Management is necessary because of

Data type basics - current, structured, complete, plausible

Many complex tasks can be associated with configuration management. But the first step is often not the perfect solution for all your problems with master data. During the first step, it is important to establish a profound data basis which we can use to start a life cycle management project together. We distinguish between basic data, which are absolutely necessary, individual data and environmental data, which can be collected additionally to complete your database:

Inventory

- Acquisition of the relevant basic and environmental data

- Digital capture

- Individual appointments

Data cleaning/checking/completion

- Acquisition from various sources (circuit diagrams, inventory lists, etc.)

- Consolidation, digitization and structuring

- Cleansing, checking and completion of existing data

Creation of a digital configuration file

- Creation of a complete digital configuration file

- Providing the data as an Excel worksheet

- Accompanying, personal expert advice on request

EICHLER life cycle management consists of three easy steps...

Your Personal Contact

- Sustainably increase plant availability

- Life cycle management / obsolescence management

- Configuration management

- EICHLER Life Cycle Check / risk analysis

- Supply strategies / Warehousing and repair management

Do you have any questions, need further information or a detailed consultation? We are at your disposal:

patrick.kroiss@eichler-service.de

+49 8196 9000-302.